Precast Concrete Treads Curb Appeal, Long Term Value Sanderson Concrete

Check out part 2https://youtu.be/1NaxpWHWHxACheap modern landscapinghttps://youtu.be/RgPE-111X_shttps://www.patreon.com/VanDamConstructionDiy concrete stepsb.

D'Bug's Life How to make Concrete Stairs

We have you covered with concrete steps pros. Enter your zip code to get started. Your home is your biggest investment - protect it by hiring certified concrete steps pros.

Kanas City Concrete Stairs Stair Treads Mobile Welding Contractors

Mike HOW TO BUILD CONCRETE STEPS: STEP 1. FIGURING THE SIZE of your concrete steps. Before you start building concrete steps, check with your local building codes to make sure you comply with any dimensions they require. Keep in mind you will also need to look into what is required for handrails.

outdoor concrete stairs Staircase design

The technology used in constructing concrete staircases enables the creation of steps that appear to float in mid-air. In uniquely designed homes, these stairs are frequently installed indoors and outdoors. These steps can lead to various areas, such as a rooftop terrace, attic, or second floor.

Removal and Replacement of Concrete Steps and Stoop Shawnee, KS Hometown

Construction of concrete stairs includes steps such as designing, preparing foundation, building formwork, placement of reinforcement steel bars, concreting, finishing and curing. Construction of concrete stairs is a difficult task that requires an engineer to study all the aspects and design it and a skilled labour to construct it.

Precast Concrete Steps Bolton Concrete Products

Concrete Steps PRECAST CONCRETE STEPS, STOOPS & OPTIONAL HANDRAILS Our concrete steps are created as a one-piece unit that requires no assembly and is easy to install. Our steps are manufactured from high-strength steel-reinforced concrete for durability.

Concrete Stairs WA Puget Sound Precast WA

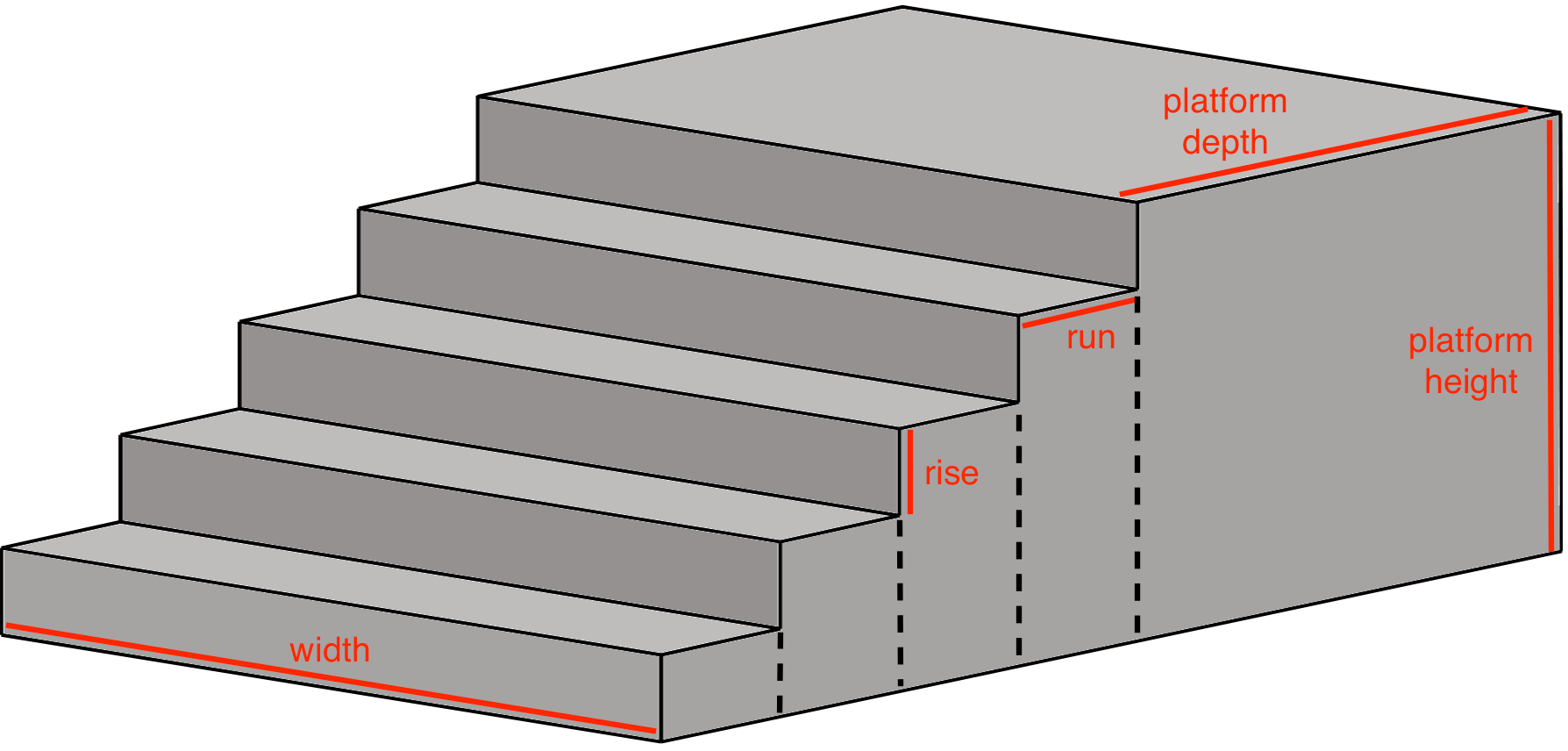

Load on the stair Figuring the correct step size is essential. Also, consider the handrails. The riser is the steps vertical face, and the tread is the steps flat face. First, you need to calculate the rise and the run of the steps you plan to construct.

Block Base For Concrete Stairs Masonry Contractor Talk

Building interior concrete stairs is a complex project, as you have to build a formwork, install a structure of reinforcing bars, pour concrete and finish the stairs with a float. As compared to regular wooden stairs, concrete stairs are more durable and rigid, therefore it is a perfect choice if you want less problems for many years in a row.

Precast Concrete Stair Treads and Steps Sanderson Concrete

Total Time: 3 days Skill Level: Advanced Poured concrete steps provide a sturdy, long-lasting transition between an outdoor surface, such as a patio, and the entry to your house. However, deciding how high and how deep (front to back) each step should be can be confusing.

Concrete Steps Calculator Estimate Yards Needed for Concrete Stairs

Concrete Steps Decorative concrete stairways offer endless design possibilities for creating a grand entrance. Concrete Forms Learn about concrete forms, and decorative liners for adding patterns and texture to concrete If you've never used step form liners before, you'll be amazed at the decorative effects you can achieve.

Outdoor Handrails For Concrete Steps MODERN INFILL Outdoor stair railing, Garden stairs

1 Equip yourself with a stair-building vocabulary. Each step consists of 2 main parts: a riser, which is the vertical part of the step, and the tread, which is the part you step on. Other important terms to know when building your stairs include:

Floating Concrete Steps Exterior stairs, Outdoor stairs, Concrete steps

Take the first step towards a safer, more stylish staircase. Call StairSteps.com now to schedule your free stair consultation and explore our range of pre-cast concrete stair treads, concrete stair treads, precast steps, and pre-engineered stairs. Experience affordability, availability, durability, and safety like never before.

Tactile Nosings for Precast Concrete Stair Treads and Steps Sanderson Concrete

The porch also has 9 linear feet of 6" step. So enter in the footing calculator, 6" depth by 12" width (always figure steps with a 12" width) by 9' length. This totals .17 cubic yards. The total concrete needed for the 3' by 3' porch will be .28 cubic yards. (.11 + .17 cubic yards = .28 cubic yards)

A Roman Steps custom precast concrete stair treads with modifications Sanderson Concrete West

Selection Shea's precast concrete stairs are available in widths varying from 4-10 feet and from 1-7 risers to provide customers the selection needed to meet their specific requirements. Our precast stairs can be faced with brick and come with either 7 or 7.5 inch risers that can be "stacked" in unlimited combinations.

Entrance steps to house Concrete Stair Steps to House Entrance — Stock Photo © jpldesigns

In this video, mason Mark McCullough helps a homeowner remove his crumbling stone steps. Then, he tours a factory to learn how precast concrete steps are mad.

A Visual Guide to Stairs BUILD Blog

How to Build Cement Steps Harrison Kral Updated: Mar. 07, 2023 Learn how to build concrete steps that look fantastic and will last 100 years. 1 / 52 Curb appeal A shabby stoop can crush a home's overall curb appeal . And while building concrete steps is more complicated than pouring a simple sidewalk, it's probably not as hard as you might think.